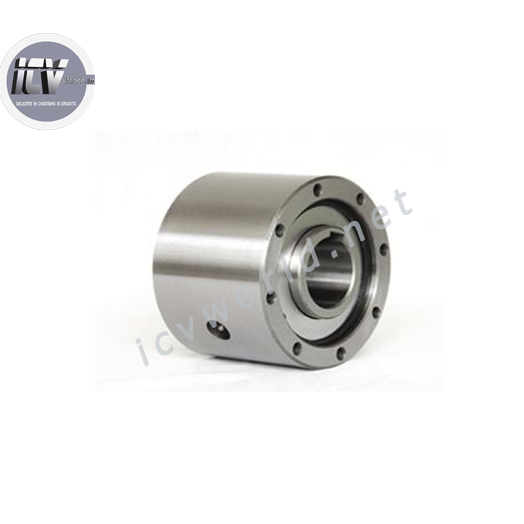

Clutch bearing MZ..G series

-

Product details

-

Checkout information

-

Shopping guide

-

Product Reviews

The working way of the clutch bearing to transmit the torque can be rotated in the smoothest possible way, and at the same time easily cut the transmission to the drivetrain to ensure the fastest and most accurate when the engine changes gear. Furthermore, clutch bearings also participate in helping the engine to operate when the car is stopped without necessarily changing the gearbox to the intermediate gear.

Clutch bearings are in line bearings. The main ability of clutch bearings is to help minimize engine wear, reduce noise and minimize sudden high temperature rises during rotation.

Clutch bearings are usually compact - compact - light in structure and in high performance.

MZ..G series

Infusion process

|

Type |

Maximum torque allowed (N.m) |

Speed exceeding allowed |

Highest repetition frequency (times / minute) |

Excessive torque (N.m) |

||||||

|

Inner groove |

Outer groove |

|||||||||

|

MZ15G |

186 |

1800 |

900 |

150 |

0.2 |

|||||

|

MZ17G |

215 |

1700 |

800 |

150 |

0.2 |

|||||

|

MZ20G |

323 |

1600 |

700 |

150 |

0.29 |

|||||

|

MZ30G-22 |

735 |

1500 |

500 |

150 |

0.39 |

|||||

|

MZ30G-25 |

||||||||||

|

MZ30G |

||||||||||

|

MZ35G |

1080 |

1400 |

300 |

150 |

0.49 |

|||||

|

MZ45G-40 |

1620 |

1400 |

300 |

150 |

0.69 |

|||||

|

MZ45G |

||||||||||

|

MZ60G-50 |

2110 |

1200 |

250 |

150 |

0.98 |

|||||

|

MZ60G-55 |

||||||||||

|

MZ60G |

||||||||||

|

MZ70G-65 |

3040 |

1100 |

250 |

150 |

1.27 |

|||||

| MZ70G | ||||||||||

Kích thước

|

Type |

Shaft Hole |

Inner Race Width A |

Outer Race Width C |

Outer Dia. B (H7) |

Inner Race Boss Dia. F |

Centering Groove Dia. E |

Chamfer K |

Mounting Tap |

Weight (Kg) |

Moment of Inertia (Kg m2) |

||||

|

Dia (H7) |

Key Slot |

Chamfer J |

PCDD |

Effective Screw Length S |

Size (H-m) Qty.-Dia.*Pitch |

|||||||||

|

MZ15G |

15 |

5*2.3 |

0.8 |

55 |

53 |

68 |

25 |

47 |

1.3 |

58 |

10 |

6-M5*0.8 |

1.3 |

0.08*10-2 |

|

MZ17G |

17 |

5*2.3 |

0.8 |

63 |

61 |

75 |

28 |

52 |

1.3 |

64 |

10 |

6-M5*0.8 |

1.7 |

0.14*10-2 |

|

MZ20G |

20 |

2*2.3 |

0.8 |

64 |

62 |

80 |

30 |

55 |

1.3 |

68 |

12 |

6-M5*1.0 |

1.9 |

0.18*10-2 |

|

MZ30G-22 |

22 |

8*3.3 |

1 |

70 |

68 |

100 |

45 |

75 |

1.3 |

88 |

16 |

6-M8*1.25 |

3.2 |

0.47*10-2 |

|

MZ30G-25 |

25 |

8*3.3 |

1 |

|||||||||||

|

MZ30G |

30 |

10*3.3 |

1 |

|||||||||||

|

MZ35G |

35 |

10*3.3 |

1 |

78 |

76 |

110 |

50 |

80 |

1.3 |

95 |

16 |

6-M8*1.25 |

4.4 |

0.77*10-2 |

|

MZ45G-40 |

40 |

12*3.3 |

1.3 |

87 |

85 |

125 |

60 |

95 |

1.3 |

110 |

16 |

8-M8*1.25 |

6.2 |

1.4*10-2 |

|

MZ45G |

45 |

12*3.3 |

1.3 |

|||||||||||

|

MZ60G-50 |

50 |

14*3.8 |

1.5 |

90 |

88 |

155 |

80 |

125 |

1.3 |

140 |

16 |

8-M8*1.25 |

9.5 |

3.38*10-2 |

|

MZ60G-55 |

55 |

16*4.3 |

1.5 |

|||||||||||

|

MZ60G |

60 |

18*4.4 |

1.5 |

|||||||||||

|

MZ70G-65 |

65 |

18*4.4 |

1.8 |

105 |

103 |

175 |

95 |

145 |

1.3 |

162 |

16 |

8-M8*1.25 |

13.1 |

6.01*10-2 |